What Does Out of Stock (OOS) Really Mean for Your Brand?

If you’ve ever heard a retailer say, “Customers are asking, but we don’t have it,” you’re already familiar with what Out of Stock (OOS) looks like on the ground. It’s that frustrating moment when a customer wants to buy — but the product just isn’t there.

Now, here’s a quick twist: while many use the terms Out of Stock and Stockout interchangeably, there’s a subtle difference worth noting.

- Out of Stock (OOS): A product is not available for sale at a specific location (e.g., a store or e-commerce site).

- Stockout: Refers to the broader supply chain disruption that caused the product to become unavailable — could be at the distributor, warehouse, or retail level.

In simpler terms: OOS is the result, stockout is the cause.

Let’s break down what Out of Stock really means, why it happens, and how your brand can tackle it like a pro.

What is Out of Stock (OOS)?

Out of Stock (OOS) refers to a scenario where a product is temporarily unavailable for purchase — whether on a retail shelf or online storefront. It means that demand exists, but supply has failed to meet it.

Why Does OOS Happen?

Several reasons can throw your stock planning off balance:

- Inaccurate demand forecasting

Example: A cosmetics brand underestimated demand for its festive lipstick bundle and missed restocking windows. - Supply chain disruptions

Example: Transportation strikes delayed liquor shipments across key urban distributors, leading to weekend stockouts. - Inventory management glitches

Example: A building materials brand’s ERP failed to sync field inventory with central systems, causing delays in replenishment. - Delays in production or replenishment

Example: An auto ancillary manufacturer faced packaging shortages that pushed delivery timelines for their new spark plug line.

Why It Matters: Impact on Sales & Loyalty

Out of Stock doesn’t just hurt your topline. It affects:

- Immediate revenue: No stock = no sale.

- Customer experience: Repeated OOS experiences tell customers, “We can’t deliver.”

- Brand reputation: If customers find your competitor’s product when yours is missing, your recall value drops.

- Retailer trust: If you can’t ensure availability, retailers might deprioritize your shelf space.

Stat: A Nielsen study suggests that 1 in 3 customers will leave a store without purchasing if their desired product is out of stock.

Real-World Impacts in FMCG

In the FMCG world, where competition is fierce and purchase decisions are impulsive, OOS can be brutal.

Use Case: A cooking oil brand launched a new SKU with a digital-first campaign. Demand surged in Tier 1 cities — but retail replenishment lagged behind. Within days, shelves were empty and social buzz turned into complaints.

Result? Missed sales and a short-term dent in credibility.

How to Minimise Out of Stock Situations

Let’s get to the good part — how to fix this.

1. Smarter Forecasting

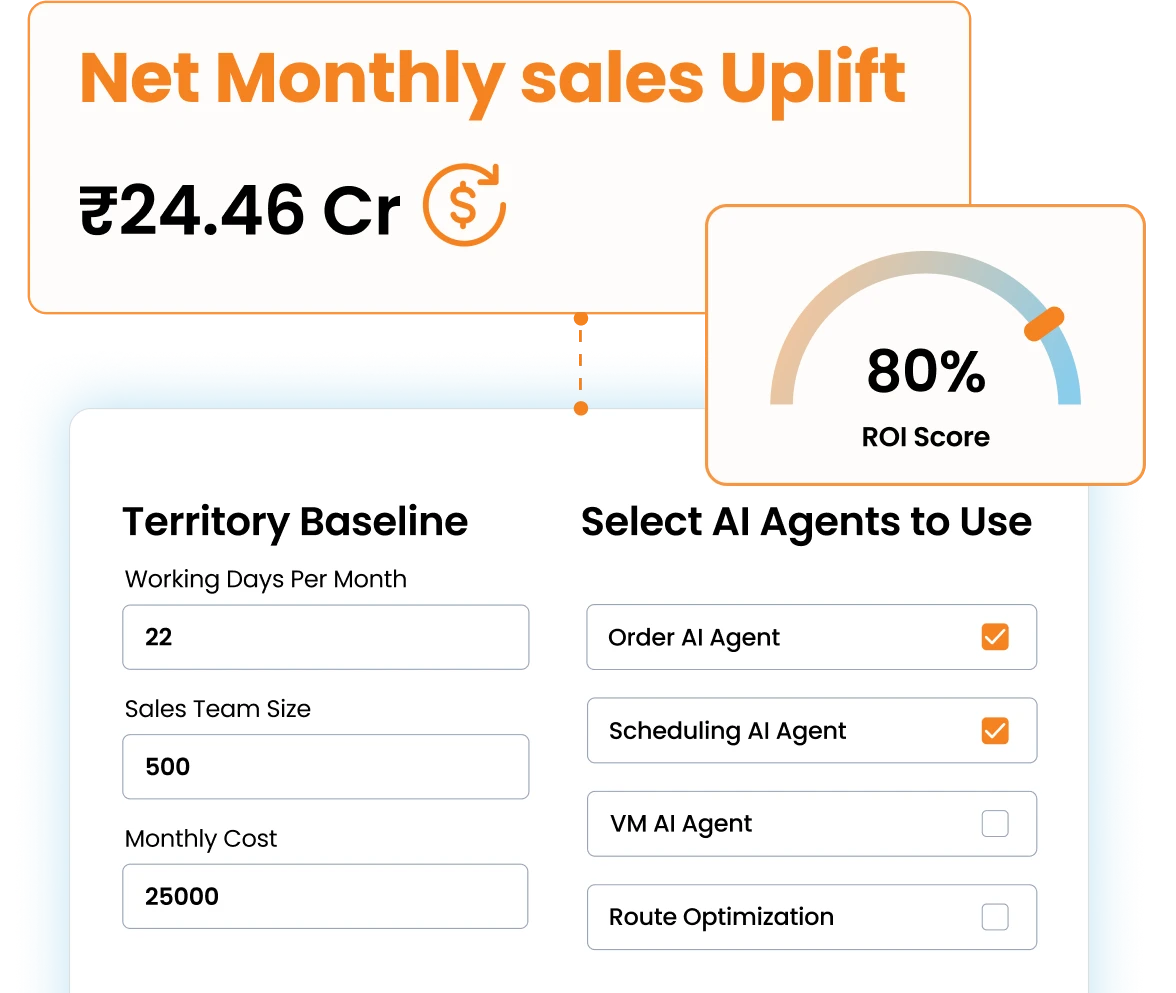

Leverage AI-powered demand prediction tools to anticipate surges.

Example: A pharma company uses regional flu data and past demand cycles to forecast peak demand for over-the-counter medication.

2. Stock Visibility in Real Time

Use digital dashboards to track what’s in stock at distributor and retailer levels.

Example: A consumer durables brand tracks retail-level stock movement during festive seasons using daily beat data.

3. Field Force Empowerment

Equip your sales reps to flag low stock during outlet visits.

Example: A cosmetics rep on BeatRoute logs a trending lipstick shade as “running low,” triggering a restock alert instantly.

4. Buffer Stocking for Key SKUs

Identify your high-velocity products and maintain safety stock.

Example: A liquor brand ensures its premium whiskey line maintains buffer stock across metro zones during holidays.

5. Supplier Coordination

Keep communication tight and timelines clear with your vendors.

Example: A building materials manufacturer maintains secondary supplier relationships to reduce downtime from raw material delays.

Final Thoughts

Stockouts and OOS moments are more than inventory hiccups — they’re critical moments of truth in your customer journey. One is the symptom, the other is the root cause.

With smart forecasting, real-time visibility, and proactive field execution, brands can not only plug stock leaks but also build stronger retail loyalty.

Book a demo with BeatRoute and learn how we help retail brands stay in stock, in control, and in demand.

About the Author

-

Nikhil is a marketing professional with a passion for enterprise SaaS and the role that technology can play in helping businesses succeed. He is passionate about enabling digital transformation for retail brands, and explores how brands can enhance their sales execution and distributor engagement with the help of technology.

Use Goal-Driven AI to Achieve Retail Sales Uplift, Today!

Join enterprises in 20+ countries that trust BeatRoute, the globally dominant AI platform for sales force automation, field sales, DMS, and eB2B

Latest Insights & Articles

Here are the most impactful articles, platform updates, ebooks and reports for you.